Search term must have more than 2 characters.

AUTOMATED LINE FOR PRODUCING ONE-CHAMBER PP BAGS

It is a fully automated line for producing bags from a semi-finished foil reeled on a coil. The foil is unwound from the coil and goes through the printers carrying out the description of the bags. Subsequently, it enters the cutting part where edges are cutaway and a cut-out for suspending is made. Another operation is the cutting of the foil into individual bags where, at the same time, small hoses are inserted into the bags for filling purposes. In the next step, two bags are sealed up at the same time on the pressing machine with an electronically controlled servo-axis. The last operation is cutting the bags in two with a knife.

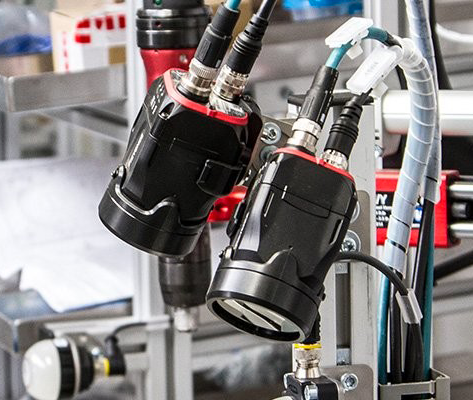

AUTOMATED WORKPLACE FOR FORMING HMG PEANUT END PIECES

Through a six-axis robot, the machine handles tubes of various shapes, diameters and lengths among the individual operations of the production procedure. The robot takes the tubes according to the set program from one of the two feeders filled by the operator with a large number of tubes prior to the starting up. Once the production is started up, the operator leaves the selected tubes and continuously comes back only to check the course of production. The workplace runs at 17 seconds’ intervals during which tubes go through six positions.

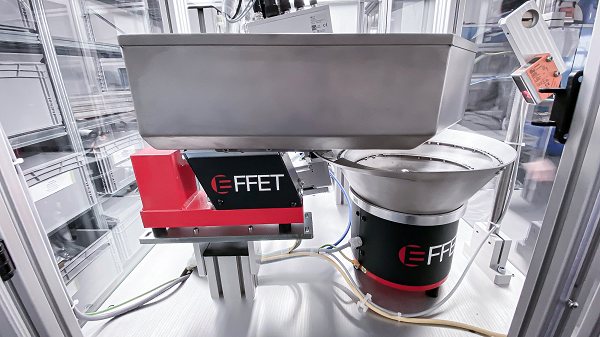

AUTOMATED WORKPLACE FOR FORMING VENEER CRIMP END PIECES

It is a complete delivery of an automated workplace for forming the end pieces of aluminium tubes. The line consists of an entry feeder, four independent handling portals, an exit feeder of the finished tubes, and two vibration feeders for the automated feeding of parts. The entry feeder serves for loading up to 300 aluminium tubes 90 - 2000 mm long. In the feeder, the feeding, the oiling of the inner diameter with an oil mist, and the centring of the aluminium tune to the initial position take place automatically.

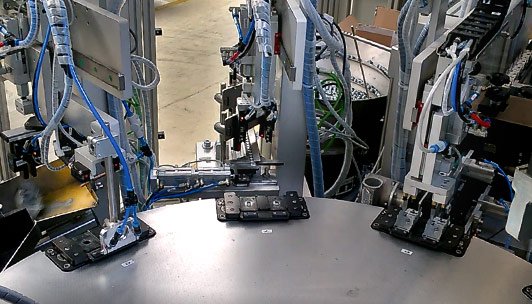

SINGLE-PURPOSE MACHINE FOR INSTALLING THE THERMOSTAT BOX

The single-purpose machine is designed as a process machine with a turntable. The turntable has 12 positions. The machine is covered by means of aluminium profiles and polycarbonate fillings.

The opening of the service door is secured through safety locks. The pace of the machine per position is 6 seconds maximum. The production capacity is at least 1 200 items per hour. One operator.

The machine is controlled through PLC S7-1200 Siemens and the HMI 7” panel. The tyre is made by Festo.